Hi

lti HIT-RE 500-SD mortar

w/

rebar (as post-installed

conn.

)

Thes

e pages

are part of the Anchor

Fas

tening

Technology Manual

is

s

ue September 2014

09 /

2014

894

Setting instruction

Rev

iew the

Material Safety Data Sheet

(MSDS) before

use for

proper and s

afe handling!

Wear well-fitting protectiv

e goggles and protective glov

es when

working

with Hilti HIT-RE 500-SD.

Important:

Observe

the installation

instruction of

the manufacturer

prov

ided with

each foil pack.

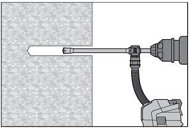

1. Drill hole

Note: Before

drilling, remov

e

carbonized

concrete; clean contact areas

(see Annex B1)

In case of aborted drill hole the drill hole shall be filled with mortar.

Drill hole to

the required embedment depth with

an

appropriately

sized Hilti TE-CD or TE-YD hollow drill bit

with Hilti v

acuum

attachme

nt.

This drilling syste

m remov

es

the du

st and cleans the bore hole

during drilling when

used in accordance

with the

user’s manual.

After drilling is

complete, proceed

to the “injection

preparation”

step

in the instructions

for use.

Drill

the hole to the required

embedment

depth using a hammer-drill

with carbid

drill

bit set

in rotation

hammer mode, a compressed air

drill or a diamond core machine.

3.

Bore hole cleaning

(Not needed with Hilti

TE-CD

and Hilti TE-YD

drill bit)

The

borehole

must be free

of dust, debris, water, ice, oil, grease and

other contaminants prior to

mortar

injection.

Just before

setting an anchor, the

bore hole must be free

of dus

t and

debris by one of two

cleaning methods described below

Compress

ed

air cleaning (CAC)

Blowing

2 times from the back of the hole with oil

-free compressed air

(min.

6

bar

at 100

litres per minute (LPM))

until return

air stream is

free

of

noticeable dust.

Bore hole diameter

≥

32 mm the compressor

must

supply a minimum air flow of 140 m³/hour.

If

required

use additional

accessories and

extensions for

air nozzle

and brush to

reach bac

k of hole.

Brushing

2 times with the s

pecified

brush

HIT-RB

size (

brush

Ø

≥

borehole

Ø)

by inserting

the round

steel brush to the back of the hole in a twist

ing

motion.

T

he brush shall

produce natural resistance

as

it

enters the

anchor hole.

If t

his is

not the case,

please use a

new

brush or a

brush with a larger diameter.

Blowing

2 times again with

compressed air until return air stream is

free of

noticeable dust.

If

required

use additional

accessories and

extensions for

air nozzle

and brush to

reach bac

k of hole.