Page 23 of European Technical Approval ETA-11/0390, issued on 27.08.2012

English translation prepared by CSTB

of the European

Technical Approval

ETA -

11/0390

Injection System Hilti

HIT-CT 1 for rebar connection

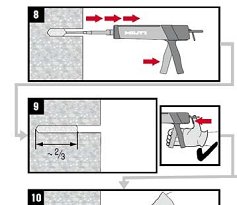

Inject mortar into borehole

Forming air pockets shall be avoided.

Injection method for borehole depth ≤ 250 mm:

Inject the mortar from the back of the hole towards the

front and slowly withdraw the mixing nozzle step by step

after each trigger pull.

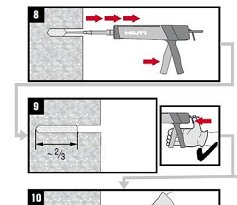

Fill holes approximately 2/3 full, or as required to ensure

that the annular gap between the rebar and the concrete

is completely filled with adhesive over the embedment

length.

After injecting, depressurize the dispenser by pressing

the release trigger. This will prevent further mortar

discharge from the mixing nozzle.

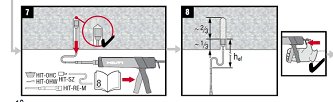

Injection method for borehole depth > 250 mm or overhead applications:

Assemble mixing nozzle, extension(s) and piston plug

HIT-SZ

(see Table 7

or Table 9).

For

combinations

of

several

injection

extensions

use

coupler HIT-VL K. A substitution of the injection extension

for a plastic hose or a combination of both is permitted.

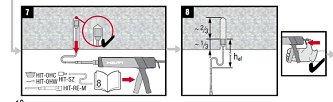

Insert

piston

plug

to

back

of

the

hole.

Begin

injection

allowing

the

pressure of

the

injected

adhesive

mortar to

push the piston plug towards the front of the hole.

Fill holes approximately 2/3 full, or

as required to ensure

that the annular gap between the rebar and the concrete

is

completely

filled

with

adhesive

over

the

embedment

length.

After

injecting,

depressurize

the

dispenser

by

pressing

the

release

trigger.

This

will

prevent

further

mortar

discharge from the mixing nozzle.

For maximum embedment

depth, see Table 7

to

Table 9.

Annex 13

Installation instruction V

Mortar injection

Injection extension

HIT-VL

Piston Plug HIT-SZ

Piston plug

HIT-SZ

Injection extension

HIT-VL