Page 21 of European Technical Approval ETA-11/0390, issued on 27.08.2012

English translation prepared by CSTB

of the European

Technical Approval

ETA - 11/0390

Injection System Hilti HIT-CT 1 for rebar connection

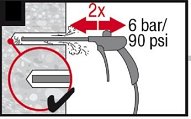

Compressed air cleaning (CAC):

Just before setting an rebar the hole must be cleaned

of dust and debris by one of the two cleaning

methods described below:

Blowing

2 times from the back of the hole with oil-free

compressed air (min. 6 bar at 100 litres per minute

(LPM)) until return air stream is free of noticeable

dust.

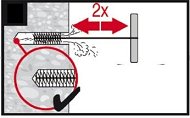

Brushing

2 times with the specified brush size (brush Ø larger

than borehole Ø) by inserting the round steel brush to

the back of the hole in a twisting motion.

The brush

shall produce natural resistance as it enters the

anchor hole. If this is not the case, please use a new

brush or a brush with a larger diameter.

Blowing

2 times again with compressed air until return air

stream is free of noticeable dust.

Deep Boreholes – Blowing

For boreholes deeper than 250mm use the

appropriate air nozzle Hilti HIT-DL (see Table 7 or

Table 9).

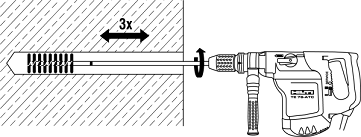

Deep boreholes – brushing

For boreholes deeper than 250mm use machine

brushing and brush extensions HIT-RBS.

Screw the round steel brush HIT-RB in one end of

the brush extension(s) HIT-RBS, so that the overall

length of the brush is sufficient to reach the base of

the borehole. Attach the other end of the extension to

the TE-C/TE-Y chuck.

Compressed air cleaning (CAC):

Air nozzle with an orifice opening of minimum 3,5mm

in diameter recommended for blowing out with

compressed air (min. 6 bar at 6 m³/h).

Annex 11

Installation instruction III

Clean bore hole - Compressed air cleaning (CAC)

min. 2x

min. 2x