Hi

lti

HIT-

RE

50

0-

SD mortar

wi

th

r

ebar (as anchor)

09

/ 2014

Thes

e pages

are par

t of

the Anchor

Fas

tening

Technology

Man

ual

is

s

ue

September

2014

533

Setting

installation equipment

Anchor size

Ø8

Ø10

Ø12

Ø14

Ø16

Ø20

Ø25

Ø28

Ø32

Rotary hammer

TE

2 – TE

16

TE

40 – TE

70

Other tools

compressed air gun or blow out pump, set of cleaning brushes, dispenser

Setting instruction

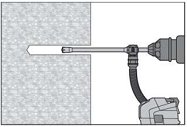

Bore hole drilling

Drill hole to

the required embedment depth with

an appropriately sized

Hilti

TE

-CD or TE-YD hollow drill bit with Hilti

vacuum

attachment.

This drilling

system re

mov

es

the d

ust and cleans the borehole

during

drilling when

using in

accordance with the user’s manual.

After drilling is

complete, proceed

to the “injection

preparation”

step in the

instructio

ns f

or use.

Drill Hole to the required

embedment

depth with a hammer

drill set in

rotation-hammer

mode using

an appropriately

sized

carbide drill bit.

Bore

hole cleaning

Just before setting an anchor, the bore hole must be free of dust and debris.

Compress

ed

air cleaning (CAC)

for all bore hole diameters d

0

and

all bore

hole depth

h

0

Blow 2 times from

the back of the hole (if

needed

with nozzle extension)

ov

er

the

hole length with oil-free

compressed

air (min.

6 bar at 6 m³/h)

until

return air

stream is

free of

noticeable dust.

Bore hole diameter

≥

32 mm the compressor

must

supply a

minimum air

flow of 140 m³/hour.

Brush 2 times with the specified brush size by inserting

the steel brush Hilti

HIT-RB

to the back of the hole (if needed

with extens

ion) in a twisting

motion and remov

ing

it.

The brush must

produce natural resistance

as

it

enters the

bore hole -- if

not the brush is too small and must be replaced

with the

proper

brush

diameter.

Blow again with compressed

air 2 times until return

air stream is free

of

noticeable dust.