Hi

lti

HI

T-RE 500-SD mortar

with

HI

S-

(R

)N

sl

eev

e

09

/ 2014

Thes

e pages

are par

t of

the Anchor

Fas

tening

Technology

Man

ual

is

s

ue

September

2014

521

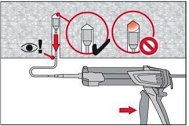

Inje

ct adhesive

from the back of the borehole

without forming

air v

oids

Inject the adhesiv

e

starting at the back of the hole, slowly withdrawing

the

mixer with each trigger

pull.

Fill holes approximately

2/3 full It is required

that the annular

gap between

the anchor

and the concrete is

completely filled with

adhesiv

e

along

the

embedment length.

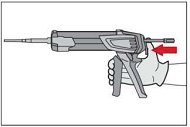

After injection is

completed, depressurize the dispenser

by

pressing the

release trigger.

T

his will

prevent

further adhesiv

e

discharge from the mixer.

Ov

erhead

installation and/or installation with embedment

depth h

ef

>

250mm.

For ov

erhead

installation the injection is

only possible with the aid

of

extensions

and piston

plugs

.

Assemble HIT-RE-M mixer,

extension(s)

and

appropriately

sized piston plug

(HIT-SZ).

Insert piston

plug to back of the

hole and inject adhesiv

e.

During injection the

piston plug will be naturally

extruded

out of the bore hole by the adhesive

pressure.

Setting the eleme

nt

Before use, v

erify

that

the element is

dry and free of oil and other

contaminant

s.

Mark and

set element to the required

embedment

depth untill working

time

t

work

has

elapsed.

For ov

erhead

installation use

piston

plugs

and fix

embedded

parts with

e.

g.

wedges

HIT-OHW

.

Loading the

anchor:

After required

curing time

t

cure

the anchor can be loaded.

The applied

installation

torque

shall not exceed given

T

max.

For detailed information

on

installation see instruction for use giv

en

with the package of the

product.

Curing time for general conditions

Data according ETA-07/0260,

iss

ue

2013-06-26

Temperature

of the bas

e material

W

orking time in which anchor

can be ins

erted and adjus

ted t

gel

Curing time before anchor

can be fully loaded t

cure

40 °C

12 min

4 h

30

°C to 39

°C

12 min

8 h

20

°C to 29

°C

20 min

12 h

15

°C to 19

°C

30 min

24 h

10

°C to 14

°C

90 min

48 h

5 °C to 9 °C

120 min

72 h